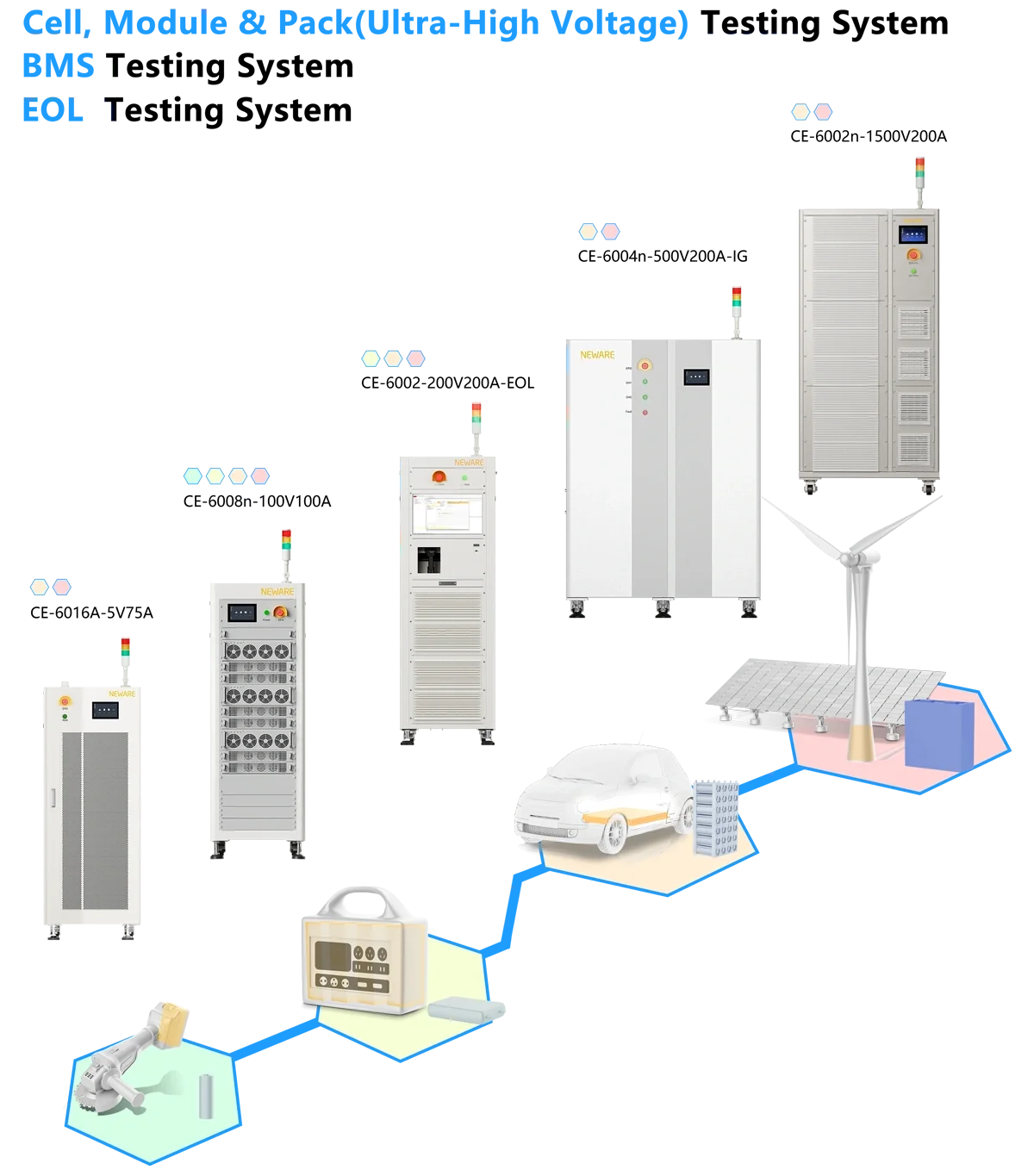

For Cell, Module, Pack, BMS and EOL Testing in uncompromising quality.

For Cell, Module, Pack, BMS and EOL Testing in uncompromising quality.

The 6 Series battery testing system is designed for testing applications in EVs, communication base stations, energy storage systems, and more.

It features a variety of testing functions, including simulated conditions and DCIR testing, which are crucial for in-depth research and evaluation of the electrical performance of battery packs.

BTS-6000

Recording Frequency

100Hz

Minimum Pulse Width

20ms

Current Response Time

≤2ms

Current Accuracy

±0.05% F.S.

Current Conversion Time ≤5ms

Voltage Accuracy

±0.05% F.S.

-

NEWARE has long provided services to Global Battery Manufacturers, Electric Vehicle Producers, Energy Storage Battery Manufacturers and Research Institutions, and has accumulated rich industry experience and technical advantages.

High dynamic response speed: it adopts advanced bidirectional high-frequency DC conversion topology technology to ensure real-time response during fast charging and discharging processes, meeting the dynamic test requirements of high-power battery.

High stability and accuracy: the system is equipped with high-performance multi-channel 24-bit ADC chips, and the sampling resolution is higher than that of traditional single-range devices, ensuring the high precision and reliability of test data.

Multi-cabinet parallel: supports multi-cabinet parallel operation for megawatt-scale ultra-high voltage output.

Battery temperature performance test: linked with environmental test chambers, it achieves battery temperature performance testing and conducts comprehensive performance evaluation.

Solutions and services: the CE-6000 series battery detection system is specifically designed for high-voltage battery packs and the new energy field, and supports various application scenarios such as power battery, energy storage battery and etc..

*CT/CE: Battery charging-discharging test system. "E" indicates that this equipment is equipped with energy feedback function.

-

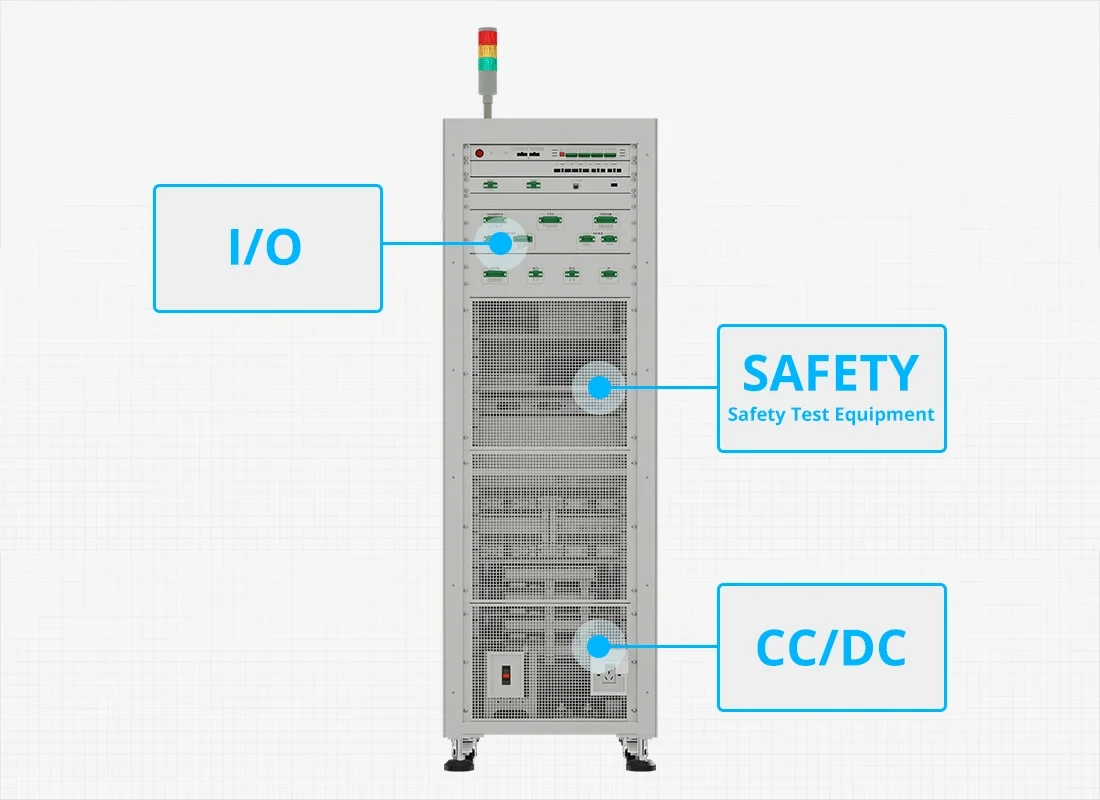

A one-stop high-precision platform for safety inspection and performance validation of power battery.

· Safety testing, IR testing, ACR, OCV, with comprehensive electrical safety checks and consistency verification.

· Tests communication buses, I/O ports, command interactions, and real-time data synchronization.

· Charge/Discharge Testing: covers CC, DC, DCIR, capacity, over-current, and over-voltage testing.

· BMS universal compatibility: built-in DBC converter for multi-standard BMS interfaces.

· Multi-device synergy: controls environmental chambers, chillers, and auxiliary equipment for complex scenario simulations.

-

Say goodbye to the explosion risks and lengthy processes of conventional battery testing.

Our system, centered on a 24CH battery simulator, a 300A high-precision current source, and 1500V insulation and dielectric withstand testing, accurately replicates extreme conditions such as over-charge, over-discharge, and temperature differences.

With in-depth coverage of 16+ test items, including balancing strategies, SOC algorithms, and multi - protocol communication, it shortens traditional week-long validation to just 5 minutes.

Its modular hardware and intelligent analysis software provide battery manufacturers and automakers with a safe, efficient, and full-stack BMS validation solution, ensuring every charge and discharge cycle is fully controlled.

Find the Right Battery Test Equipment for Your Needs

CE-6000 Cell Testing System Small Current

CE-6000 Cell Testing System Large Current

CE-6000 Module Testing System

CE-6000 Pack Testing System

CE-6002-1500V200A

CE-6001n-3000V200A

CE-6002-200V200A-EOL

CE-6’S-BMS-24S300A

Enjoy transparent prices, guaranteed payments, safe transactions, and a full selection of Neware’s high-performance products in one place.